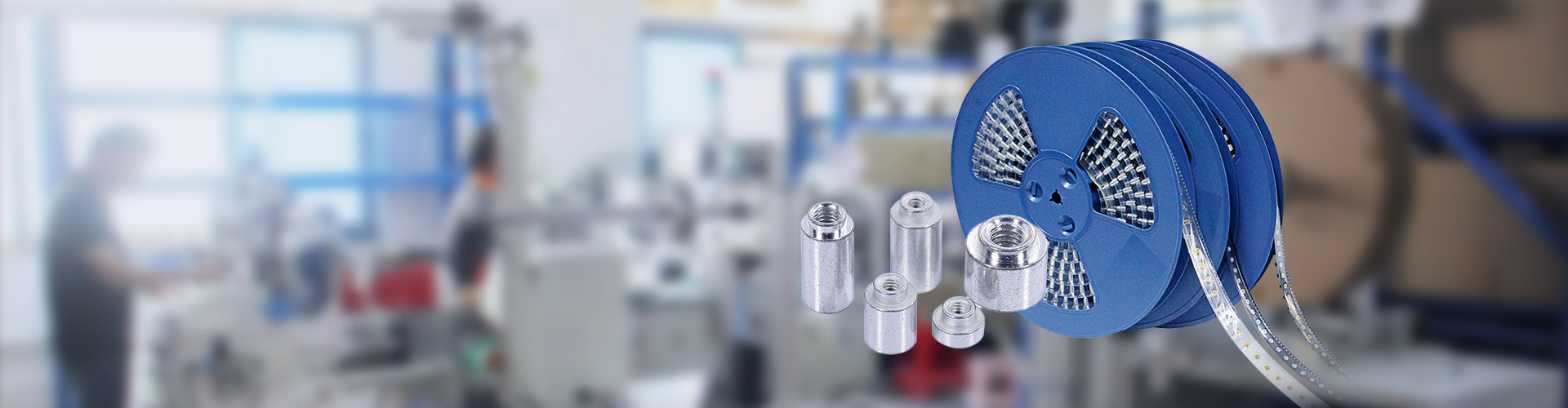

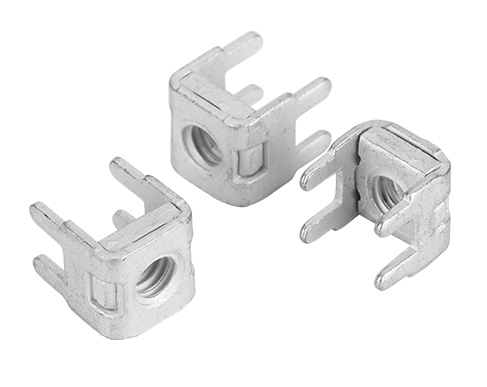

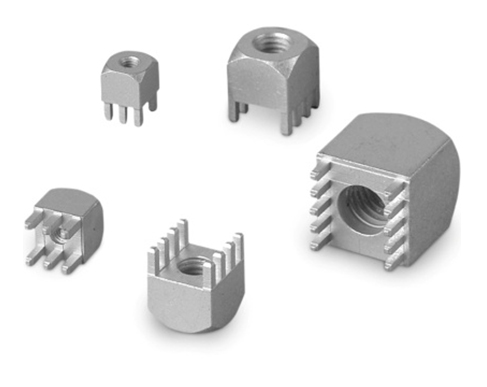

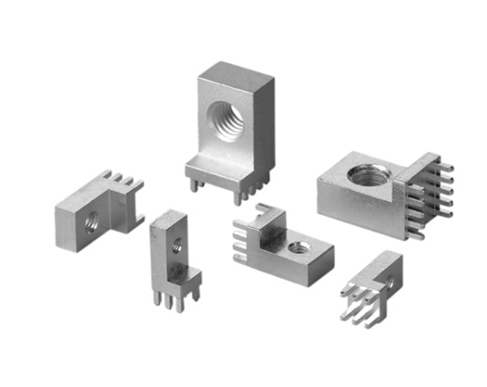

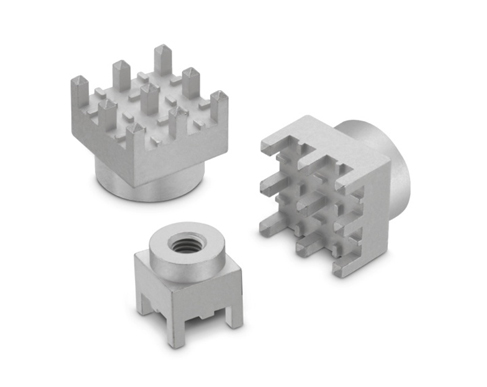

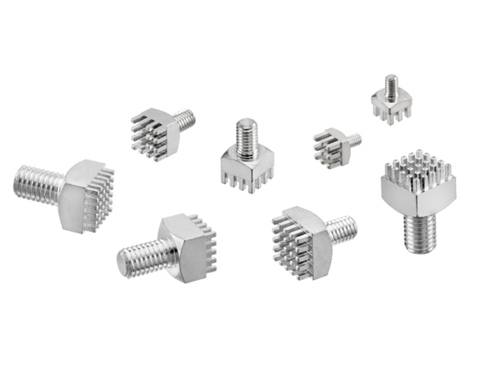

SMT surface mount nut post is a miniaturized nut or screw commonly used for fastening and fixing connectors around PCB boards, also known as SMD surface mount fasteners or PCB soldering nuts. Introduced an ideal hardware solution for printed circuit board applications that require higher-level electrical and mechanical connection points. The product features are small size, light weight, and can be fastened in small spaces, improving the compactness and aesthetics of the product. By using the standard PCB mounting process of SMT patching, furnace curing, and reflow soldering for installation, the parts can be directly soldered onto the PCB board, greatly improving production efficiency and saving production costs compared to loose nuts. It can be compatible with existing SMT processes in the factory, so the installation efficiency of nuts (bolts) for high-speed SMT mounting will significantly increase by several orders of magnitude compared to traditional fasteners. At the same time, it can significantly reduce manual operations and save labor costs. Reduce scrap rate and avoid potential adverse risks caused by manual operations.